Dead-Time Optimization Techniques in GaN-Based Motor Drives

GaN Talk – Andrea Gorgerino

Apr 08, 2024

Using GaN to Kill the Dead time in Motor Drive Designs

In the realm of power conversion, dead time is a necessary yet burdensome aspect of design, forcing engineers to make concessions to ensure reliability. However, recent advancements in technology, particularly the emergence of gallium nitride (GaN) FETs, are challenging the status quo. In this blog, we delve into the impact of dead time on performance in motor drives, and how GaN FETs are reshaping the landscape of power electronics design.

Understanding Dead time

Dead time refers to the delay between turning off one power device and turning on another, essential for preventing simultaneous conduction and potential short circuits. For example, in synchronous buck converters, the simultaneous conduction of two devices can lead to additional losses, higher operating temperatures, and even catastrophic failure.

Control dead time, which is inserted by the controller, ensures a positive effective dead time. Calculating this dead time is a complex process that involves considering factors such as propagation delay, gate resistor values, and FET turn-ON/OFF times. GaN devices, due to their lack of body diode reverse recovery and faster switching times, require smaller dead times compared to silicon MOSFETs, making them a compelling choice for high-performance applications.

Motor Drive Dead Time

Dead time in motor drives can significantly impact efficiency, but for some nuanced reasons that require a closer look at how an inverter and a motor interact.

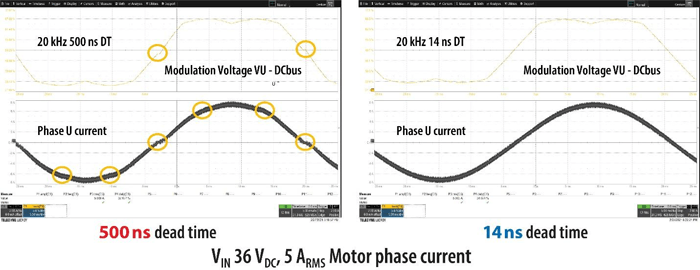

One major impact of dead time is increased distortion during zero-current crossing. This is because during dead time both high side and low side device in a leg of the inverter are off, and therefore the actual voltage being applied to the motor depends on the sign of the current. At the zero-current crossing this voltage abruptly changes sign, creating a voltage distortion which results in higher-order harmonics in the motor current waveform. These currents do not create any useful torque, but lead to increased losses in the motor windings, and overall reduced efficiency, as shown in Figure 1.

Figure 1: Comparison of dead time effect on zero-crossing distortions in a sinusoidal motor drive

Figure 1: Comparison of dead time effect on zero-crossing distortions in a sinusoidal motor drive

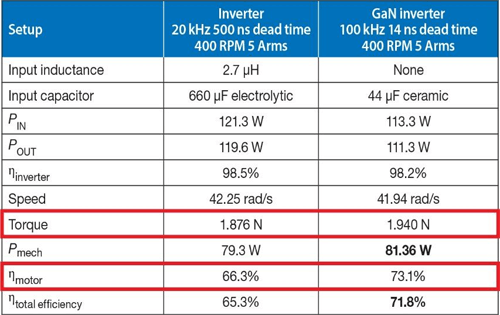

Reducing dead time in motor drives is crucial for improving efficiency. By minimizing dead time, distortion can be reduced, leading to smoother current waveforms and lower losses. This ultimately results in improved motor efficiency and overall system performance as shown in figure 2.

Figure 2: Combined effect of dead time reduction and PWM frequency increase on a sinusoidal motor drive.

Figure 2: Combined effect of dead time reduction and PWM frequency increase on a sinusoidal motor drive.

Gallium Nitride-Based Motor Drives: A Game-Changer

GaN-based motor drives offer several advantages over more traditional motor drives, which typically use silicon-based components. Some key advantages include:

- Higher Efficiency: GaN FETs have lower on-resistance and faster switching speeds compared to silicon MOSFETs. This results in reduced conduction losses and switching losses, leading to higher overall efficiency in motor drives.

- Smaller Size and Weight: GaN FETs can operate at higher frequencies, allowing for the use of smaller passive components such as inductors and capacitors. This reduction in component size and weight makes GaN-based motor drives more compact and lightweight.

- Higher Power Density: The smaller size of GaN-based motor drives allows for higher power density, meaning more power can be delivered in a smaller footprint. This is particularly beneficial in applications where space is limited.

- Faster Response Times: The faster switching speeds of GaN FETs enable faster response times in motor drives, which can improve dynamic performance and responsiveness of the system.

Use Cases for GaN-Based Motor Drives

Figure 3: Some examples of use cases for GaN-based motor drives

Figure 3: Some examples of use cases for GaN-based motor drives

The advantages that GaN-based motor drives offer makes them well-suited for various motor drive applications that require high efficiency, compact size, and reliable performance. Some specific applications include:

- eMobility: GaN-based motor drives enhance efficiency for ebikes, escooters, and small automated guided vehicles (AGV), which is crucial for extending the range of these electric vehicles. The higher frequency capability enables the design of smaller, lighter, and more power-dense systems.

- Industrial Automation: GaN-based motor drives can enhance the efficiency and reliability of motor control systems in industrial automation applications. The faster response times of GaN FETs can improve the precision and speed of automated processes.

- Robots/Cobots: GaN FETs provide higher efficiency, faster response times, and smaller size compared to traditional silicon-based drives. These advantages result in improved overall performance, energy efficiency, and compactness of robotic systems.

- Drones: These same advantages of high efficiency, fast response times, and small size, make GaN FETs the ideal choice for drone applications. These advantages result in longer flight times, improved maneuverability, and increased payload capacity for drones.

- Medical Devices: GaN-based motor drives can be used in medical devices, such as surgical robots and medical imaging equipment, to improve performance and reliability. The faster response times of GaN FETs can enhance the precision and accuracy of these devices, while their higher temperature operation can ensure reliable performance in medical environments.

GaN Performance Enables Dead-Time Optimization in Motor Drives

GaN enables better dead-time optimization for motor drive applications primarily due to its superior performance characteristics compared to traditional silicon-based components.

- Switching Speed: GaN FETs have faster switching speeds compared to silicon MOSFETs. This allows for more precise control over the dead-time, as the turn-off and turn-on times of the GaN FETs are significantly shorter. This faster switching speed allows for tighter control of the dead-time

- Reduced Gate Capacitance: GaN FETs have lower gate capacitance compared to silicon MOSFETs. This means that they can be turned on and off more quickly, allowing for shorter dead-times without the risk of shoot-through currents. This enables more efficient operation and better optimization of the dead-time in motor drive applications.

- Zero Reverse Recovery Charge: GaN FETs do not have a body diode like silicon MOSFETs, which eliminates the reverse recovery charge associated with silicon devices. This reduces the effective dead-time required in motor drive applications, as there is no need to account for the recovery time of the body diode.

Unlocking Efficiency: Using GaN FETs for More Efficient, More Compact Motor Drive Designs

Dead time has long been a necessary compromise in power electronics design. However, with the advent of GaN FETs, this compromise is becoming a thing of the past. By enabling smaller dead times, GaN FETs reduce losses, improve control, and enhance efficiency in motor drive applications. While not eliminating dead time entirely, GaN FETs represent a significant step forward in mitigating its effects and unlocking new possibilities in power electronics design.

If you want to revolutionize your motor drive designs, take the next step and explore the possibilities with GaN technology. For assistance, reach out to one of our GaN Experts.